Product Description

Description

- Space-saving and reliable complete system for position, speed and length

- Up to 0.008 mm/pulse (incremental, complete system) or up to 0.003 mm/step (absolute, consisting of individual components: measuring wheel, spring arm and encoder) for excellent measurement results

- Suitable for any surface

- Quickly mounted and adjusted

Prose

For over 25 years, Wachendorff Automation has developed and manufactured systems and rotary encoders for worldwide use in the areas of mechanical and plant construction, lift construction, mobile machinery and renewable energies. More than 1,500 realised customer variants demonstrate their flexibility and absolute focus on the customer's needs. Owing to the high mechanical and electrical stability of their rotary encoders and systems, we provide a five-year warranty - which is unique in the world!

With these systems, the positions, speeds and travel lengths of conveyor belts, film/paper webs or cardboard packaging, for example, can be recorded safely and efficiently.

They meet the highest requirements in an ideal way with the LMSMA2x/3x measuring systems. Constant and accurate measurement results through optimal, low-slip measurement in the most varied conditions arising from:

- Adjustable pressure

- Coordinated measuring wheels for every surface

- Selectable resolutions from 1.0 to 0.008 mm/pulse (incremental, complete system) or up to 0.003 mm/pulse step (absolute, consisting of individual components: Measuring wheel, spring arm and encoder)

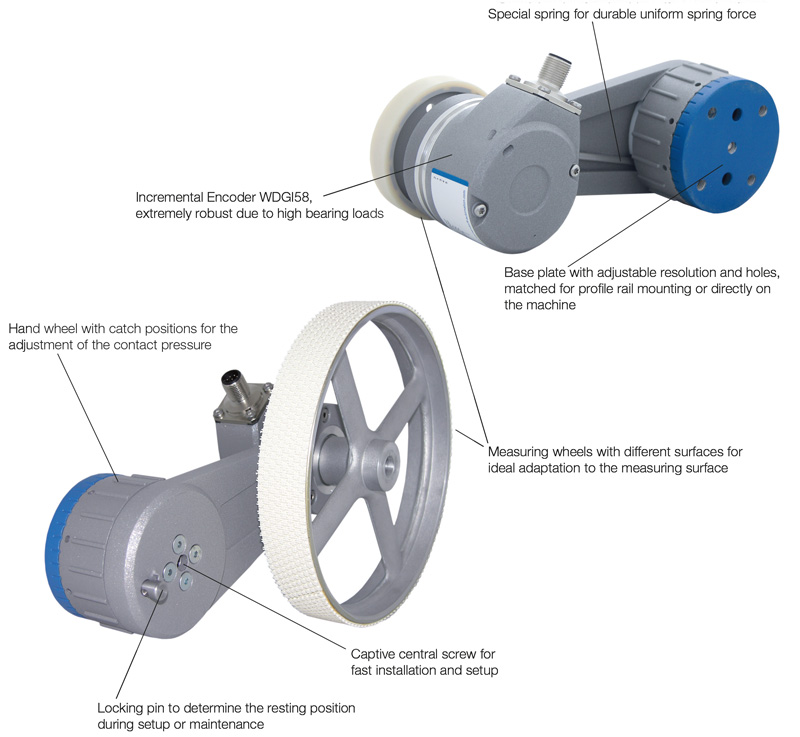

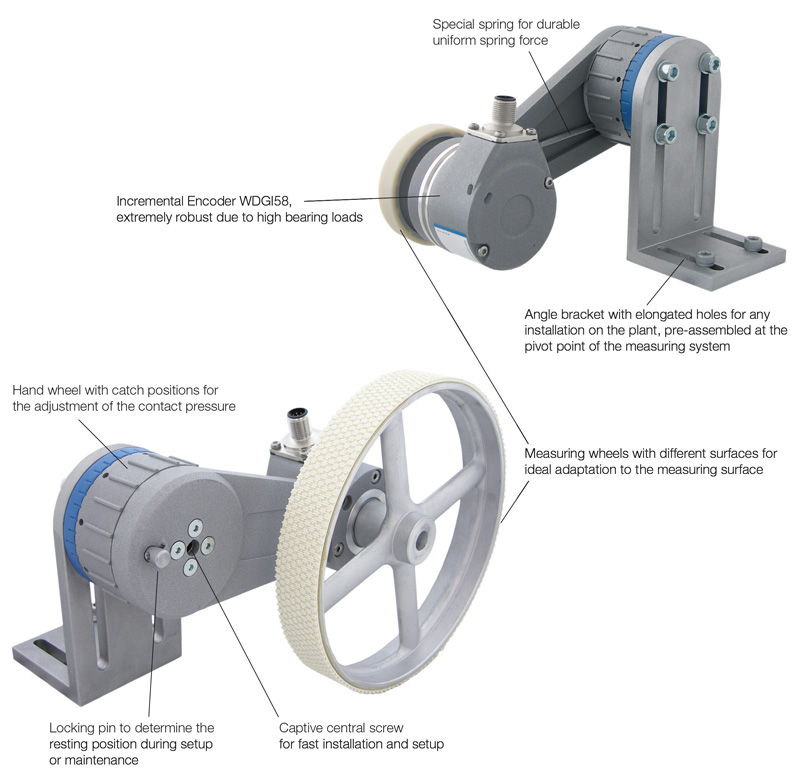

Small space requirement thanks to its compact design. Long service lifetimes thanks to the high mechanical robustness of all the components. Fast and flexible mounting on the machine.### 36 Alignment Positions

The newly developed hand wheel with its 10° resolution levels allows for 36 alignment positions. In combination with the elongated holes of the angle bracket, you get much more room for the installation.

Easily Adjustable Preload

With the new systems, the spring preload is adjustable in steps from 5 N to a maximum of 30 N preload.

Calibration Without Disassembly

The preassembled systems for installation in the machine or readjustment during commissioning remain mounted.

Fixation in Resting Position

During machine setup or maintenance in particular, it is possible that the length measuring system is not designed to run. The LMSMA systems offer the possibility to fix the spring arm in a resting position. The spring arm is then returned to the working position and continues to work at the previously set pressure. You will see that there are a number of good reasons for using the LMSMA length measuring systems.## Quickly Mounted - Directly On The Machine

To assemble, simply loosen the base plate from the hand wheel and attach it to the machine at the position defined by you. The dimensions of the holes in the blue base plate are adapted to the current attachment profiles on the market. The captive central screw enables the measuring system to connect to the base plate. Now simply adjust the preload and tighten the central screw.

Easily Mountable - With Pre-assembled Angle

Perfect Grip and Extremely Low Concentrical Tolerance

The length measuring system LMSMA with the measuring wheel KW (Adapter for encoder with conical shaft) has been specially developed for applications requiring very low concentrical tolerance. The optimised system has up to 10 times better concentrical tolerance than a standard length measuring system and is therefore suitable for applications requiring very high accuracy. In combination with our high-resolution incremental encoders an unbeatable team.